Central Puerto S.A.

Cogeneration San Lorenzo – Terminal 6. EPC Instrumentation and Control

Client: Central Puerto / Argentina

Plant: Cogeneration San Lorenzo Central 6.

Reference: EPC instrumentation and control.

Scope of supply: The contract comprises the engineering, detailed engineering, supply, programming, installation and commissioning of 800 instruments and valves, PCS 7 Control System (DCS), fire detection system, SOTR system, voice and data system, tank level measurement (TIMS), steam and water analysis system, overfilling system, project documentation and data management.

Grupo Albanesi S.A.

Cogeneration Power Plant ‘Central Timbúes’. Supply of BOP control system – Green field plant.

Client: Albanesi / Argentina

Plant: Timbúes Cogenerations.

Reference: Green Field Plant BOP.

Scope of supply: New cogeneration power plant. Green Field Generation Project. It comprises: development of plant’s BoP control system, executed on the Siemens PCS7 platform; detailed engineering for instrument installation, instrumentation and control cableways ; design, construction and testing of control panels; programming of BoP control logics - including boiler control-; instruments supply, wiring and field buses; instrumentation, panles and control installation services, , integration of all skids that make up the Plant Balance; complete system commissioning and Startup.

Central Puerto S.A.

Client: Central Puerto / Argentina

Plant: Nuevo Puerto and Puerto Nuevo.

Reference: BMS Migration and combustion control System Update.

Scope of supply: Migration and improvement with certified hardware for burner safety system in units 14, 15 and 16.

Replacement of the combustion regulation system upgrading from pneumatic to digital technology of unit 13.

Nucleoeléctrica Argentina S.A.

Client: Nucleoeléctrica Argentina S.A.

Plant: Atucha II Nuclear Power Plant

Reference: Assistance services in I&C for commissioning.

Scope of supply: Provision of engineers, technicians and instrumentation specialists to carry out the commissioning of control and safety systems for the 745 MW (35,000 hh) Atucha II Nuclear Power Plant.

Enel Generación Argentina

Central Costanera. Modernization of the water-steam cycle chemical dosing system

Client: Enel Generación Argentina

Plant: Central Costanera.

Reference: Modernization of chemical dosing.

Scope of supply: Engineering, supply, manufacturing, installation and commissioning of steam water quality monitoring systems for thermal cycles 5, 6, 7, 8, and 9 with due automatic control of chemical dosing pumps.

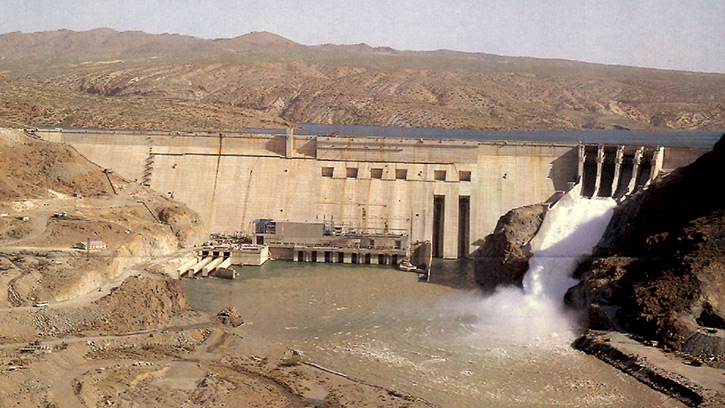

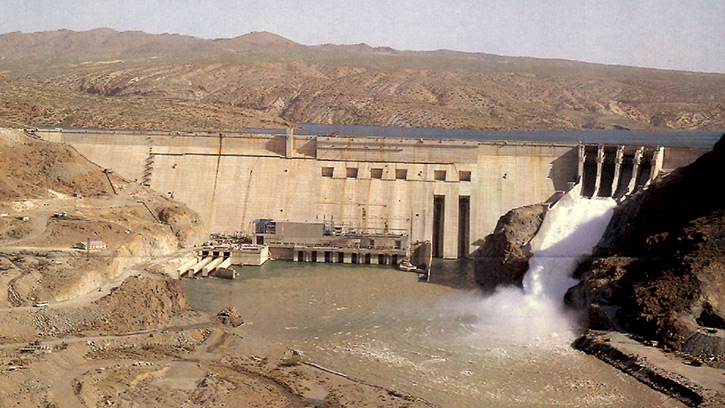

Hidroeléctrica Piedra del Águila

Plant Control System Migration to PCS7

Client: Central Puerto S.A. / Argentina

Plant: Piedra del Águila.

Power: 1400 MW.

Reference: Control System Migration.

Scope of supply: Migration of the entire plant control system from Bailey90 to Siemens PCS7. Replacement of IO modules by new ET200M I/O. This migration was carried out with the entire plant in full operation, without preventing any generation unit from working.

PCS7 migration development of the joint frequency control applications with HPP El Chocón.

Pampa Energía S.A.

Pichi Picún Leufú Hydroelectric Plant (Former Petrobras Energy). Plant Control System Update

Client: Pampa Energía S.A. / Argentina

Plant: Pichi Picún Leufú hydroelectric plant.

Power: 261 MW.

Reference: Plant Control System Update.

Scope of supply: Replacement of plant’s Infi90 system controllers by the updated version: BRC410. Provision of new system’s communication cards, and update of the PGP supervision platform, together with an engineering station upgrade. Given the features of the new controllers, the existing logic on each controller logic was streamlined and optimized.

AES Generación Argentina

San Nicolas Thermal Power Plant. New Control Master DCS

Client: AES Generación Argentina / Argentina

Plant: San Nicolás Thermal Power Plant – Block 5.

Power: 350 MW.

Reference: New DCS Master Control.

Scope of supply: Control of the Thermal Cycle for a 3 fuel (gas, fuel oil and coal) conventional thermal unit, with 16 burners for each of them. Automated processes: combustion master for the 3 fuels, turbine master and integration of the Data Logger and the EHC.

Grupo Albanesi S.A.

Client: Grupo Albanesi / Argentina

Plant: CT Sorrento, Block 3.

Reference: New DCS and Instrumentation.

Scope of supply: New Boiler Control System (BCS), Field Instrumentation and SIL 3 Safety System (BMS) with new turnkey smart flame detectors. The upgrade of intelligent valve actuators and electrical protections via Profibus DP is included.

PlusPetrol Energy

Tucuman Thermal Power Plant. Update of the Control Room Operation System

Client: PlusPetrol Energy S.A. / Argentina

Plant: Tucumán Thermal Power Plant.

Power: 440 MW.

Reference: Update of the Control Room Operation System.

Scope of supply: Replacement of the operator stations and OIS/OIC database by PGP 3.1 system and implementation of the reporting system; Total renovation of the control HW, installing BRC 400 and streamlining the control logics and improvements in the HW and SW architecture of the system servers.

Hidroelectrica Piedra del Aguila

Bailey90 Plant Control System Upgrade

Client: Hidroeléctrica Piedra del Aguila S.A. / Argentina.

Plant: Piedra del Aguila.

Power: 1400 MW.

Reference: Control System Update.

Scope of supply: Replacement of the existing generation control system in Digital MicroVax terminals, with a new MFC03 processor and implementation of automatic generation control (AGC) loops, calculation of limits, joint power control (CCP) and replacement of the operating terminal stations with new Power Generation Portal (PGP) servers and operation clients.

Pampa Energía S.A.

Pichi Picún Leufú Hydroelectric Plant (Former Petrobras Energy). Plant Control System Update

Client: Pampa Energía S.A. / Argentina.

Plant: Pichi Picún Leufú Hydroelectric Plant

Power: 261 MW.

Reference: Plant Control System Update.

Scope of supply: Replacement of the existing generation control system in Digital MicroVax terminals, with a new IMMFP12 processor and implementation of automatic generation control (AGC) loops, calculation of limits, joint power control (CCP) and replacement of the operating terminal stations with new Power Generation Portal (PGP) servers and operation clients.

Centrales de la Costa Atlántica S.A.

Necochea Thermal Power Plant. New Control and Instrumentation System

Client: Centrales de la Costa Atlántica SA / Argentina

Plant: CT Necochea Blocks I and II

Reference: New Control and Instrumentation System.

Scope of supply: New Control System (BCS), Data Acquisition (Datta Loger) and Safety (BMS) SIL 3; partial replacement of field instrumentation and replacement of flame detectors with new intelligent detectors.

UTE Uruguay

Central Battle y Ordóñez. Control system update

Client: Adm. Nacional de Usinas y Trasmisiones Eléctricas / Uruguay

Plant: Central Batlle and Ordóñez

Power: 213 MW

Reference: Control System Update.

Scope of supply: Update of the human-machine interface (HMI) of the distributed control system of units 5 and 6. Migration of OIS42 /3 and OIC42 /3 consoles to ABB Power Generation Portal (PGP) V3.2 consoles in a client/server structure. New historical SQL database server and Web Server. Total renovation of the control HW, installing BRC 400 and rationalizing the control logics.

Pampa Energía S.A.

Central Piedrabuena. New U29 and U30 Control System

Client: ABB / Pampa Energía / Argentina

Plant: Luis Piedra Buena Thermal Power Plant

Reference: New Control System U29 and U30.

Scope of supply: Development, Training, Pre-commissioning and Start-up Engineering Services for the replacement of the Thermal Cycle control systems and update of Interlocks in Units 29 and 30. It consists of a partial revamping of a Network 90 system to INFI 90 and the complete replacement of Bailey France systems in both generation blocks.

Central Puerto S.A.

Nuevo Puerto Combined Cycle. HMI update and Historical Records and Reports server

Client: Central Puerto SA.; Bs As / Argentina

Plant: Combined Cycle

Reference: HMI Update and Historical Records and Reports server.

Scope of supply: Updating of the human-machine interfaces (HMI) and of the historical records and reports server of the Harmony INFI 90 distributed control system. Installation of 4 new PGP V4.1 servers with 3 dual-monitor Operation Clients and a SQL Server with server/client Crystal Report application for data access and reports from the intranet.

Hidroeléctrica El Chocón S.A.

Cliene: El Chocón SA / Argentina

Plant: C.H. Arroyito.

Reference: HMI update.

Scope of supply: Update of human machine interfaces (HMI) migrating SW Tenore 1.0 to PGP.

Alto Paraná S.A.

Puerto Piray. Boiler and cogeneration control update

Client: Alto Paraná SA./ Argentina

Plant: Puerto Piray.

Reference: Boiler Control System and Cogeneration Control Update.

Scope of supply: Update of the human machine interfaces (HMI) of the Freelance distributed control system V4.1 to V9.1; Partial renewal of the Control HW from DCP 10 to AC800F with 16MB redundant, integration of the Freelance Rack I/Os to the processors via CANBUS and expansion of the system I/Os via S800 I/Os. New boiler control functions, generator control (machine capacity and load shedding) and 132KV Substation command were incorporated.

Nucleoeléctrica Argentina S.A.

Atucha I Nuclear Power Plant. Steam sample conditioning system and analytical measurement

Client: Nucleoeléctrica Argentina S.A.

Plant: Atucha I Nuclear Power Plant.

Reference: Steam Sample Conditioning System.

Scope of supply: Sample conditioning system with 14 steam lines and provision of chemical analytical instrumentation.

Nucleoeléctrica Argentina S.A.

Embalse Nuclear Power Plant. Steam Sample Conditioning System

Client: Nucleoeléctrica Argentina S.A.

Plant: Embalse Nuclear Power Plant.

Reference: Steam Sample Conditioning System.

Scope of supply: Sample conditioning system for 28 steam lines and Deuterium Analyzer System from NASA, CN Embalse.

Nucleoeléctrica Argentina S.A.

Embalse Nuclear Power Plant. Assembly instrumentation and control Emergency Generator System SBDG

Client: Nucleoeléctrica Argentina S.A.

Plant: Embalse Nuclear Power Plant.

Reference: Instrumentation and control assembly Emergency Generators System SBDG.

Scope of supply: Installation of emergency generators, including of instrumentation and control. Supply and implementation of fire detection system.

EPEC

Pilar Plant. Flame detectors supply and commissioning

Client: EPEC

Plant: Pilar Thermal Power Plant

Reference: Supply of Flame Detectors.

Scope of supply: Supply, installation and commissioning of flame detectors for Turbo group No. 3 of 75 MW.

Central Puerto S.A.

Puerto Nuevo. Flame detectors supply and commissioning

Client: Central Puerto S.A.

Plant: Central Nuevo Puerto

Reference: Supply of Flame Detectors.

Scope of supply: Supply, installation and commissioning of 16 flame detectors for boiler 13 of 250 MW.

Yacyretá Hydroelectric Plant

Units 9 and 20 Control System Migration

Client: Entidad Binacional Yacyretá

Plant: Yacyretá Hydroelectric Plant

Reference: Units 9 and 20 Control System Migration.

Scope of supply: The Yacyretá Binational Company is an important link in the comprehensive solution for the supply of electrical energy in our country, producing energy in a sustainable manner. The modernization of the Yacyretá Hydroelectric Power Plant begins by putting into operation a transformation process according to the dynamics of the time. In this stage, the intervention of the control systems of Generation Units 9 and 20 will be carried out, by replacing the original technology with another of the latest generation based on resources of the 4.0 era.

GlaxoSmithKline (GSK)

Client: GlaxoSmithKline

Plant: Victoria

Power: 100 kW

Reference: Photovoltaic solar park for total injection into the electricity grid.

Scope of supply:A photovoltaic solar plant for self-consumption was built and put into operation located on the roof of its laboratory facilities in Victoria, Province of Buenos Aires. The system has a generating capacity of 100 kW and is made up of 204 monocrystalline solar panels, it will allow for significant energy savings and will prevent the emission of 135 tons of greenhouse gases per year, thus helping to prevent global warming.

Proinged

Photovoltaic solar park Oriente 300 kW

Client: PROINGED

Plant: Oriente

Power: 300 kW

Reference: Photovoltaic solar park for total injection into the electricity grid.

Scope of supply:Oriente is a population located in the south of the Province of Buenos Aires, whose main activity is agriculture and livestock. This population was selected by Proinged to improve the quality of its electricity supply through its own photovoltaic energy park, which supplies electricity to the population and thus improves the quality of life of its inhabitants.

LC TECH S.A. Solar plant

45 kW photovoltaic solar roof in our offices

Client: LC TECH S.A.

Plant: Office

Power: 45 kW

Reference: Photovoltaic solar park for self-consumption and injection into the electricity grid.

Scope of supply:LC Tech SA is a company committed to the economic, social and environmental sustainability of its activities.

With a power generation of 45kW and a battery bank designed specifically for our levels of electricity consumption, from sunrise to sunset we are completely self-sufficient, generating zero consumption from the electricity distribution network.